Cleaning Process Before Corn Flour Production

Why should clean the corn?

There is mixed with a lot of impurities such as stones, leaves etc. at the time of harvest corn. So, corn must be cleaned up before processing, the cleaning process is basically the same as wheat and rice, but the corn kernel is bigger, it will be easier with the aid of corn processing equipment to remove impurity.

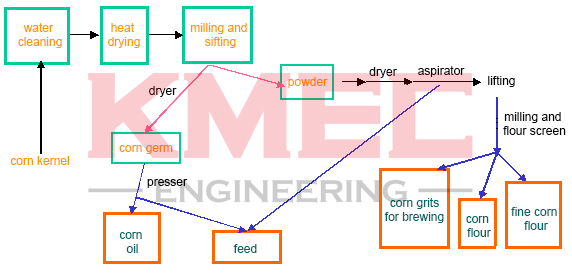

Corn Flour Production Process

Corn flour is made by crushing, sieving, settling, drying and grinding.The following processing procedures are the complete technical flow of maize milling production, but not all procedures are required in actual production. The exact maize flour production process is strictly designed taking into account the requirements of grain milling, investment costs, production capacity, etc. (Latest project: Setting up a maize flour mill in Congo at low cost >>)

Complete Maize Flour Milling Production Process Flow Chant

Cleaning Process

Cleaning maize contains various dust and mustard, organic and inorganic impurities. In order to ensure safe production and product quality during the production and processing of maize flour, the impurities present in the maize must be cleaned. The main methods used to clean maize are screening and windrowing. Cleaning equipment includes vibrating screens, specific gravity de-stoners, permanent magnetic drums and wheat cleaners.

- Step 1 : Screening, using a vibrating screen to clean the corn is very necessary.

- Step2: Destoner of cleaning equipment will be used before corn processing.

Remove stone can use a gravity stoner. The specific gravity destoner is used to remove parallel stones from the maize. Due to the large size of the maize, the flattening of the grains and the specific gravity, etc., the air volume should be increased appropriately during operation, the wind speed should be increased appropriately, the wind speed through the fish scale holes is about 14 m/s and the height of the projection of the fish scale holes should be increased appropriately to 2 mm. When operating, attention should be paid to the state of movement of the material on the fish scale sieve, the air volume should be adjusted and the stone discharge from the stone discharge opening should be checked regularly.For corn kernel size is larger, suspension speed is higher, air volume should be increased when using gravity stoner. Corn magnetic impurities usually adopt the horseshoe magnets to clean. Or you can also use a rotary drum magnet to remove magnetic impurities.

- Step3 : The permanent magnetic drum is used to remove magnetic metal impurities from the maize and should be placed in front of the ground maize entering the crusher to prevent metal impurities from entering the crusher.

- Step4: The wheat washing machine cleans mud and dust from the maize. The ash content of the cleaned maize can be reduced by 0.02% to 0.6%.

Typical Project→ 100T Corn Flour Milling Project in Nigeria

→ 80TPD Corn Flour and Grits Plant in Uganda

ABC Machinery is one of the largest distributors and suppliers of grinding and production equipment in China. KMEC,the factory we work with, has become a manufacturer integrating R&D, production, sales and after-sales. If you are interested in the performance of the equipment or how to set up a grinding plant, please contact us, here we can provide a complete service.