Cost To Start Rice Mill Plant

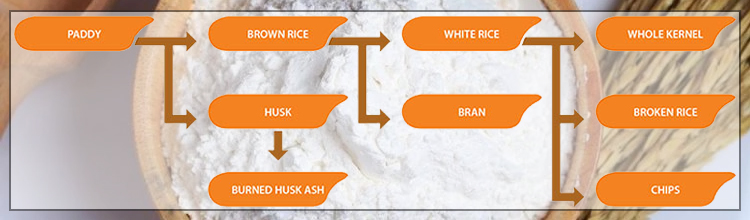

Rice is the finished product of paddy that is made after cleaning, hulling, milling and finishing of the rice. It contains nearly 64% of the nutrients in Rice and over 90% of the nutrients that are all needed by the human body. Rice is the most widely consumed staple food in the world, especially in Asia and Africa.

Rice Milling

Setting up a rice mill plant would be very profitable in where rice is the main agriculture plants, such as China, India, Indonesia, Vietnam, Thailand, Myanmar, Philippines, Brazil, Pakistan, etc. So, how much does it cost to build a rice mill? What equipment is required? (Related post: Cost of Setting up a Maize Mill in Uganda >>)

Small Rice Mill Plant at Factory Price

In order to meet more customer’s requirement for rice production, we developed newly automatic rice mill machine that adopts advanced grain processing technology to ensure stable performance and good economic effects.

Rice Mill Plant

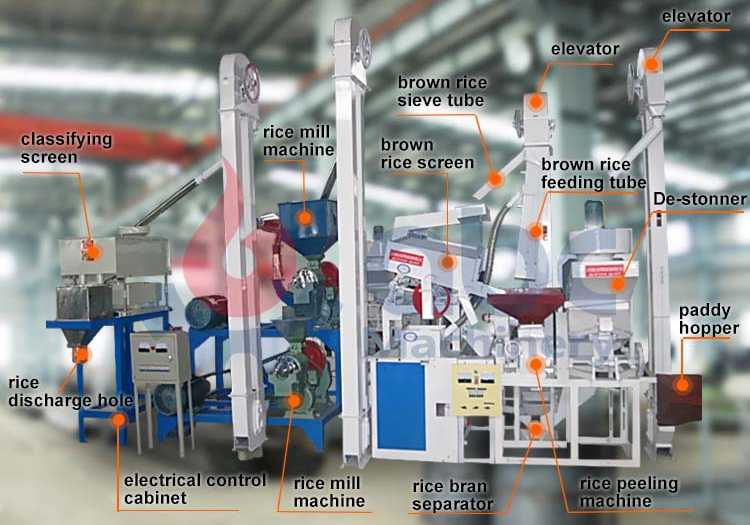

This small scale rice mill plant has the functions of cleaning, stone removal, husk peeling and broken rice classification. It is pretty easy to turn rice into polished rice efficiently. It is the ideal equipment for rice milling or rice hulling. Just like other flour mill machine provided by ABC Machinery, it is featured with high yield, less crushing and excellent effects.

| Equipment | Capacity | Power | Weigth | Dimension |

|---|---|---|---|---|

| BS15C Rice Mill Plant | 0.6-0.8 T/H | 42 KW | 1500 KG | 5000x3000x3700 MM |

This small rice processing machine covers an small area, has compact structure, high yield, no residue. It is also easy to maintain and operate. The rice produced can meet the national standards. It is an ideal equipment for market town, farms, individual proprietors or small business. If you are also interested in flour mill machine for small business, please contact us to get more technical information!

Complete Rice Milling Machine Working Steps

The elevator lift the raw material rice to de-stoner, rice after cleaning will respectively go to rice huller and gravity separation sieve, separate the bran and brown rice at the same time. The rice bran discharge from fan ( or processed by crusher), and the brown rice to rice huller processed into white rice. (Read more: Maize Milling Process >>)

Small Rice Milling Plant Working Video

Buy high quality rice mill plant for rice hulling and milling: HOT sale rice mill plant offered by grain processing equipment manufacturer or supplier, guide on process of rice production and how to start rice milling business with limited cost in Tanzania, Egypt, Morocco, Ghana, South Korea, etc.

Total Cost to Start Rice Mill Plant

The total cost of establishing a rice mill cannot be stated as different factors determine the value. Let’s see what these factors are and how they will affect the cost of setting up a rice processing plant. It will help you draw an estimated cost and prepare the budget for opening a rice mill. (Read more: Prices of Milling Machines >>)

Rice Mill Plant Machinery

- Cost of Land and Building

To set up a rice mill plant, you will need a land that can accommodate all of the machinery, raw materials, products, and other similar things. The price of the property varies from area to area or from country to country. It is more in developed areas and less in underdeveloped areas such as villages. Similarly, you will have to either set up a whole new building designed according to your needs or buy an already designed structure. Both will affect the cost in different ways.

- Cost of Raw Material

Another factor that will affect your cost of setting up a whole new plant is the raw material that you are going to use. As you are setting up a rice mill plant, so, primary raw material will be paddy. Its cost will depend on various factors such as:

- Which type of rice you are buying?

- How much rice you buy per month?

- From where do you need to transport it?

- Who are your suppliers? Are they local or foreigner?

- Cost of Rice Mill Plant Machinery

Rice mill plant machinery, which contains different equipment such as mill machine, cleaning equipment, etc. varies in price depending on the quality, size, and production capacity of the machine. Small scale mill plants will cost less because it has a small size and consumes less energy as compared to large size mill plants. Good quality machinery will need less maintenance, consume less energy, and will have high production capacity. But it may cost more than other types of machinery. (Read more: Milling Equipment Manufacturers >>)

To save the cost of rice mill plant, choosing a reliable rice milling machine supplier would be a key step. ABC Machinery offers various models of rice milling machine to different needs. Mini rice milling machine is the BEST selling equipment among our product catalogue. The price is relatively cheaper, about 1,000$ can buy one for home use or small capacity of rice milling. If you are interested in rice milling, we can supply customized plan to help select the most cost effective equipment, welcome to contact us directly!

- Cost of Labor

Equipment, building, and raw material will be of no use if you do not have a skilled and efficient labor to run the plant. You will need workers to run the machinery, to maintain it, to create new strategies in order to increase the output, and to manage the whole rice mill plant. Their salary will be based on how skilled they are in doing what they do.The total cost of labor is determined by the number of workers you need to run the milling plant.

These are the main factors that will determine the total cost of establishing a rice mill plant. Once you have made the right investment into this business, you will enjoy a huge profit in the future if you keep it well managed and maintained. If there are any questions, please contact us without hesitation!