15 TPD Wheat Flour Manufacturing Factory Layout in Pakistan

Wheat is an essential global staple, containing more protein and calories than any other grain crop, and is the most important of the cereals, followed by corn, barley and sorghum.

Therefore, from an investment point of view, there is an excellent opportunity to make money in the wheat flour milling business. Typically, wheat is ground into different finenesses of flour. The entire processing process of wheat flour production requires special flour making equipment.

Investing in Wheat Flour Milling Plant Business

ABC Machinery is a professional manufacturer and supplier of wheat milling machine with factory price and best service from process design to after-sales service. Welcome to contact us for more information about wheat milling equipment for sale. (Related articles: China wheat milling production line for sale >>)

15 Tons/Day Wheat Milling and Processing Machine Exported to Pakistan

Recently, a customer from Pakistan purchased a 15TPD wheat milling line from ABC Machinery. He is planning to set up his own wheat milling plant in his hometown in Pakistan and is inclined to start his investment with a small flour milling business. (Read more: Wheat milling manufacturing plant cost>>)

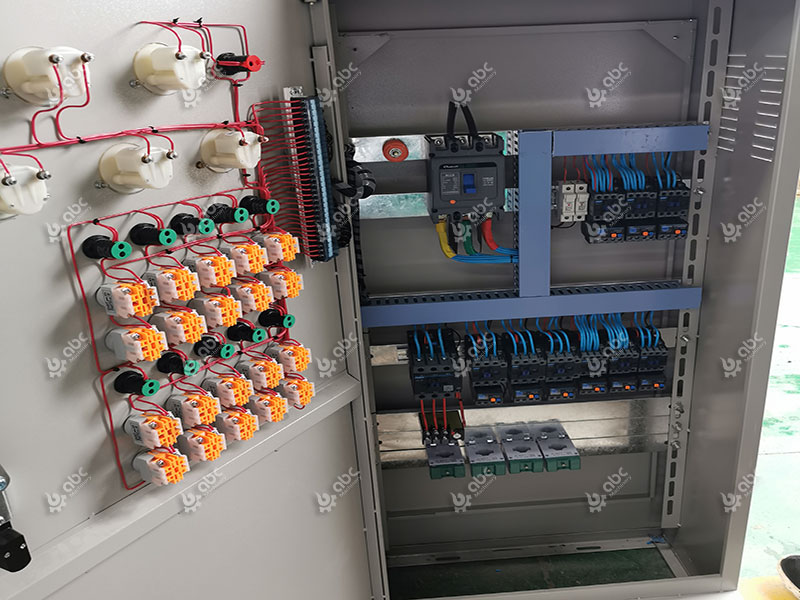

This mini wheat milling processing plant is designed with the process of cleaning - washing - wetting - milling - sieving - packing. A complete wheat milling process is used: part of the flour produced is made for food and part is sold locally. Here is the photo of the equipment. Our professional engineers provided him with a complete wheat milling processing solution. If you are interested in also starting a wheat milling business, please feel free to contact us for detailed business plans, project reports and the latest equipment prices and construction costs.

Wheat Flour Production and Processing

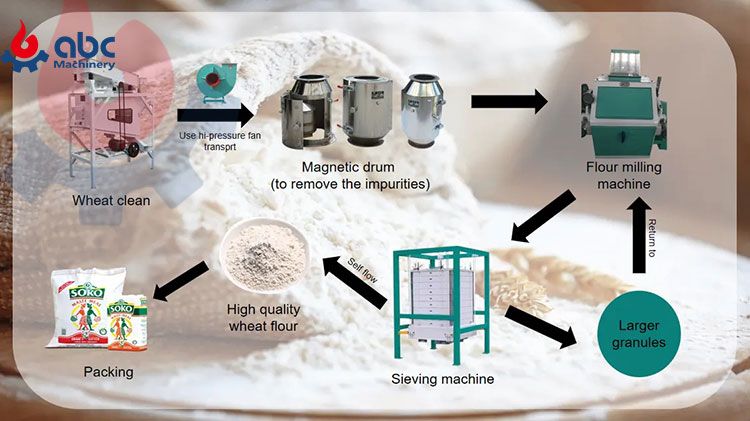

Wheat Flour Production Processing Flow Chart

- 1. Cleaning

Mainly to clean up the wheat straw, stones, broken wheat and other impurities that affect the flour yield. Experiments have shown that this process can remove up to 99% of impurities, ensuring higher quality flour. The main equipment are: wheat beater, de-stone machine, wind selection machine etc. According to the quality requirements of wheat flour making, various flour mills will have certain differences.

- 2. Wheat Washing

Wheat washing involves cleaning wheat with water to reach an optimal moisture content of around 14% to 16%, which can improve the toughness of the wheat skin and reduce the mechanical strength of the wheat endosperm, so that when grinding, so that the wheat skin is not ground to pieces and affect the quality of flour, and the tempered endosperm makes the mill roller wear less, while reducing energy consumption. Generally speaking, add more water to high gluten wheat and relatively less to low gluten wheat.

- 3. Wheat Wetting

After washing, the wetting process involves storing the wheat in water for a period of time, typically between 8 and 24 hours, depending on the wheat variety and temperature. High gluten wheat usually takes longer, and it also takes longer to wet wheat in winter. After watering and wetting, the wheat is called incoming wheat, and the moisture of incoming wheat is controlled at 14% to 16%. If the moisture content is too high, it can affect the sieving process later on.

- 4. Milling and Sieving

Divided into heart grinding system and skin grinding system, the mill crushes wheat into large bran, small bran, large endosperm, small endosperm, coarse powder and fine powder, and then puts different materials into different grinding trays to grind, with sieving and clearing powder. This is a very complicated process that needs to be adjusted by experienced flour masters to achieve the best results. Finally, we get fine flour, coarse bran and fine bran.

- 5. Mixing of flour ( option )

To meet specific customer requirements, different wheat flours can be mixed in certain proportions. This allows for the adjustment of various flour characteristics to meet customer needs.

- 6. Packing

The final step in the process is packaging the finished flour for distribution.

Video: Wheat Flour Manufacturing Factory Layout

To learn more about wheat milling plants and start your own wheat flour processing business, please feel free to contact us!