Complete Soy Protein Separation / Isolate Project Setup

Protein Separation Techniques, also called soya protein separation methods, through a series of process and machinery to separate the protein from the Non-GMO soybean material.

Soya Protein Seperation Extraction Line Flow

Soya Protein Seperation Extraction Plant for Sale

Production Input: 2-40 TPH

Suitable Raw Materials: Soya bean, low temperature soya meal

Offering Service: Customized business plan, project design, cost analysis, factory layout, equipment manufacturing, protein plant on-site installing & commissioning, and operation guide.

Setup Design for 100TPD Soya Protein Separation Production Line

| Project Name | Production Section | Note |

|---|---|---|

| 100TPD SPI Production Project | 100T Soybean Pretreatment | |

| 80T Low Temperature Solvent Extraction | ||

| 15T Crude Oil Refinery | ||

| SPI Extraction | ||

| 50m³/h Water Treatment System | ||

| Boiler | User supply | |

| Wastewater Treatment | Need emission standard | |

| Fiber Processing Equipment | For animal or for human? |

Buy soya protein separation production plant from soya protein separation methods equipment manufacturer or supplier at factory price, get FREE technical instruction of soya protein separation methods process and business plan to set up soya protein separation production project in Kyrgyzstan, Pakistan, Bangladesh, Uzbekistan, Saudi Arabia, etc., at low cost.

Protein Separation Techniques Details

Raw Material Pretreatment

Soyabean Pretreatment Flow

- Cleaning section: to remove the iron impurities, large impurities, stalks, and stones.

- Tempering section: to increase the protein content, ensure the invariance of soybean protein.

- Peeling section: to remove the skin of soybeans to increase the protein content of soybean meal.

- Softening section: to improve the plasticity of soybean raw materials, improving the leaching effect.

- Flaking section: to destroy the cell structure of the oil, ensuring that the rolled billet is thin and uniform.

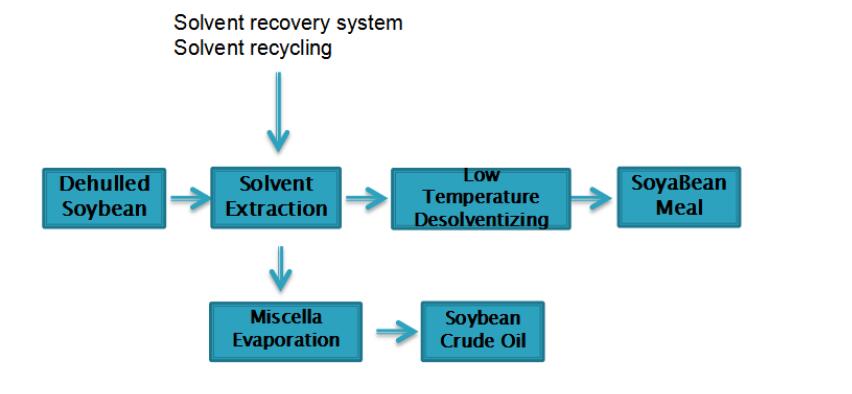

Low Temperature Solvent Extraction Process

Solvent Extraction Process FLow

Advanced drag chain extractor, stainless steel grid plate, frequency conversion speed regulation for feeding and discharging, automatic control of feeding level, stable production, low residual oil in meal, and low dissolution consumption.

Low Temperature Meal Index

| Protein Content | Moisture | Resid | Meal soluble | NSI |

Finished Meal (with skin) |

Powder Degree (60 mesh) |

|---|---|---|---|---|---|---|

| ≥53% (In dry basis) | ≤10% | ≤0.5% | ≤500PPM | ≥82% | ≤1.5% | ≤3% |

Soya Protein Separation Process

Soya Protein Separation Process Flow

-

The first step is to dissolve and extract. Utilizing the solubility characteristics of soybean protein, use weak alkaline aqueous solution (NaOH) to soak low-temperature defatted soybean meal to extract soluble proteins and low molecular sugars, and then use a centrifuge to separate insoluble fibers and solid residues.

-

The second step is acid precipitation, add a certain amount of aqueous hydrochloric acid solution to the dissolved protein solution to adjust its pH, and then use a centrifuge to separate the precipitated protein gel.

-

The third step is neutralization, homogenization, sterilization and spray drying. The separated protein is homogenized, sterilized, vacuum flashed and pressurized and then spray dried to obtain a powdered soybean protein isolate product.

Protein Dry Area

Soya Protein Drying Area

The drying tower machine is mainly used to dry the materials coming from the protein wet area. The key point of the drying tower is temperature control. Temperature will directly influence the quality of the protein and whether the main tower is deformed.

Advantages of Setting Up Soya Protein Separation Plant

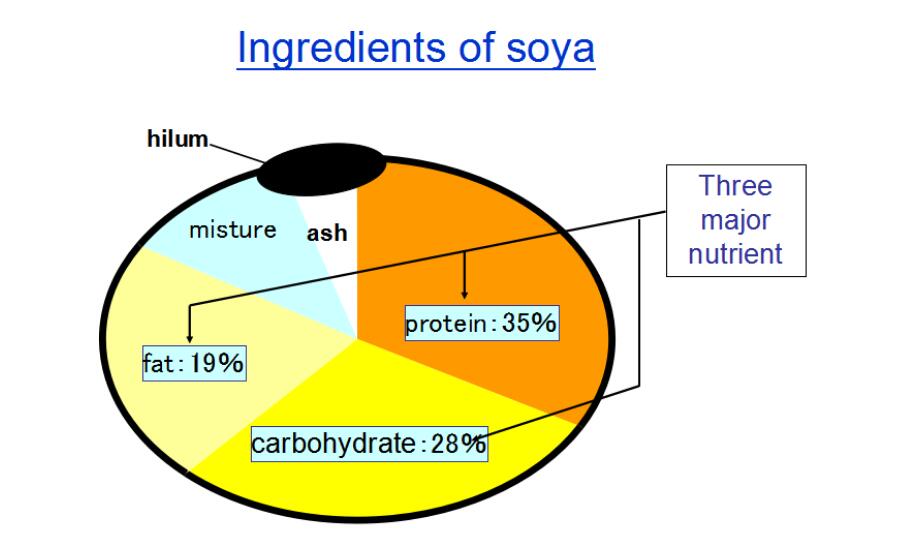

- Health benefits of soya protein. There is 35% of protein in the soybean, and with soya protein, you can reduce the amount of neutral fat in your body and lose weight, meanhile effectively preventing the risk of heart disease, reducing the risk of cardiovascular disease and enhancing immunity and exercise ability.

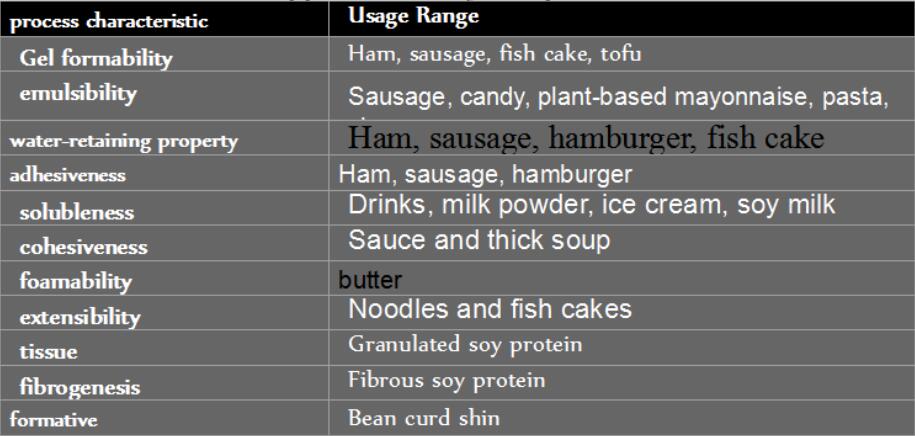

- Wide applicaiton of soya protein. As an important food additive, soy aprotein can be used in wide fields, like sausages, hamburgers, shaomai food to effectively protect oil and water, and provide special taste of meat products.

- High return of soya protein separation techniques. From the picture above, we can see the soya has wide produciton area in the world, meaning that high demand of soya protein methods. If you have enough raw materials and budget, it is suitable for processing soya protein for sale, or for investment.