Maize Flour Processing Plant Cost & Turnkey Solutions

Maize flour milling plants represent one of the most scalable and capital-efficient models in industrial flour milling. From a global perspective, maize accounts for over 30% of total cereal production, with annual output exceeding 1.1 billion tons, making maize flour mill investment logic highly representative of industrial flour mill business potential. Investors can extrapolate this logic to wheat, buckwheat, and rice flour mills with similar capital and operational frameworks.

Maize Flour Mill Investment Potential: Scalability & Profitability

Explore a comprehensive guide on maize flour processing plant cost, including investment analysis, equipment selection, factory layout, and strategies to ensure profitable flour mill operations.

Maize Flour Milling Plants Investment Potential

Maize flour plant business model shares common cost drivers with wheat and other grain mills, including raw material handling, milling efficiency, labor intensity, and energy consumption. Typical industrial maize flour mills target extraction rates of 65–75%, similar to standard wheat flour mills operating at 70–78%, reinforcing their comparability.

From an investment standpoint, maize flour mills are widely adopted because degermination and milling technologies are well standardized. Maize flour production plants highlight three main principles: production scalability, equipment modularity, and market-driven product selection. By applying these principles, ABC Machinery offers turnkey solutions adaptable to wheat, rice, or buckwheat milling projects. (Related Reading: Corn Processing Industry Market Demand )

Key Considerations for Investors:

-

Production Scale: Daily output ranging from 5–50 tons influences equipment selection and space planning.

-

Market Demand Analysis: Assess local consumption trends to determine flour type and packaging needs.

-

Turnkey Engineering Solutions: Implement modular setups for flexibility across different flour varieties.

Partner with ABC Machinery’s team and leverage our proven maize-based engineering models to clarify your maize flour mill investment strategy.

Maize Processing Plant Cost Analysis For Flour Mill Setup Cost Decisions

A detailed breakdown of maize processing plant cost enables investors to evaluate profitability and operational efficiency. Capital expenditure for a maize flour mill typically ranges from $150,000 to $2 million, depending on daily capacity and automation level. Operational costs, including energy consumption of 25–40 kWh per ton of maize, labor, and maintenance, should be systematically analyzed.

Capital Cost Breakdown

| Category | Percentage of Total Cost | Description |

|---|---|---|

|

Equipment |

60-70% |

Milling machinery, sieving systems, and conveyors |

|

Infrastructure |

15-20% |

Building construction, storage, and utility installation |

|

Permits & Licensing |

5% |

Local regulatory approvals and safety certifications |

|

Working Capital |

10-15% |

Raw materials, packaging, and initial operational reserves |

Stepwise Cost Evaluation Using A Maize Flour Mill

-

Step 1: Define maize flour plant capacity, typically 10–50 tons per day, based on target market demand.

-

Step 2: Allocate the investment budget across maize milling equipment, civil works, utilities, and startup working capital.

-

Step 3: Select modular processing equipment that can later adapt to wheat, rice, or specialty flour production.

-

Step 4: Model ongoing costs, including maize-specific energy consumption (25–40 kWh per ton), labor requirements, and scheduled maintenance.

-

Step 5: Forecast maize flour sales revenue, calculate breakeven timelines, and set measurable profitability targets.

Work with our engineering team to develop a maize flour mill cost analysis and turnkey investment plan tailored to your production goals.

Key Equipment Configuration In Flour Mill Business Plans

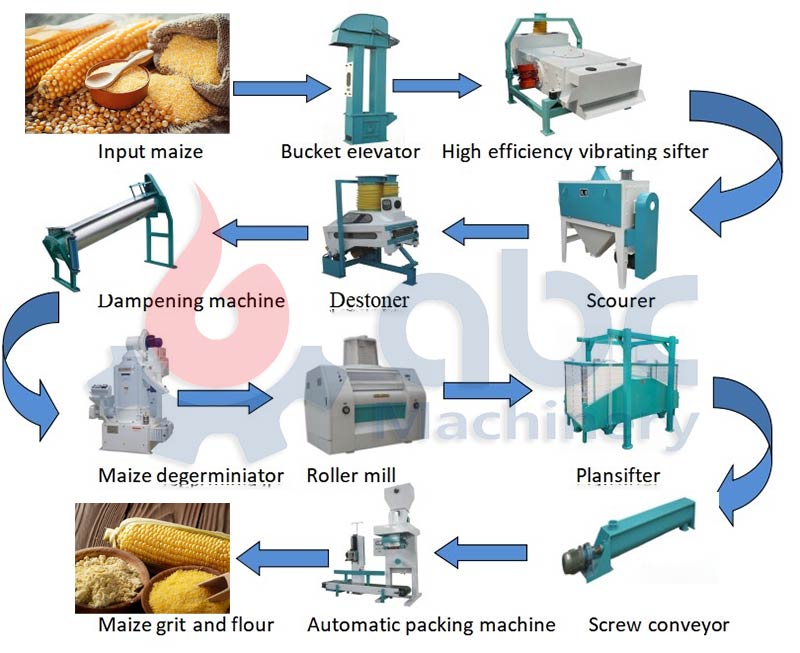

Maize Flour Milling Equipment Flow: From Cleaning to Packaging

In a maize-based flour mill business plan, equipment selection should follow the actual maize flour processing flow, from raw grain intake to finished product packing. This approach ensures capacity matching, cost control, and long-term operational stability when evaluating overall flour mill setup cost.

A typical maize flour production line includes cleaning and conditioning equipment, degermination units, milling machines, sifting systems, conveying equipment, and packaging lines. Each equipment group plays a defined role in protecting yield and controlling operating cost.

-

Primary Milling Equipment:

Roller mills are widely used in maize flour plants for controlled grinding after degermination, with a typical capacity of 1–5 tons per hour per unit. Hammer mills are often applied in pre-grinding or coarse milling stages and can reach 4–6 tons per hour, depending on maize hardness and moisture level.

-

Sifting And Classification:

Plansifters and centrifugal sifters separate flour grades and control particle size distribution, directly affecting product quality and market value.

-

Conveying And Handling Systems:

Bucket elevators, screw conveyors, and pneumatic lines must be sized to match milling capacity, avoiding bottlenecks that can reduce overall output by 10–15% if improperly designed.

Equipment Modularization For Multi-Flour Production

-

Modular flour mill equipment allows future conversion to wheat, buckwheat, or rice flour processing with limited mechanical adjustments.

-

Interchangeable roller sets, quick-change sieves, and adjustable conditioning systems support flexible product strategies without rebuilding the entire plant.

Work with our engineering team to configure maize flour mill equipment that balances capacity, flexibility, and long-term operating cost control.

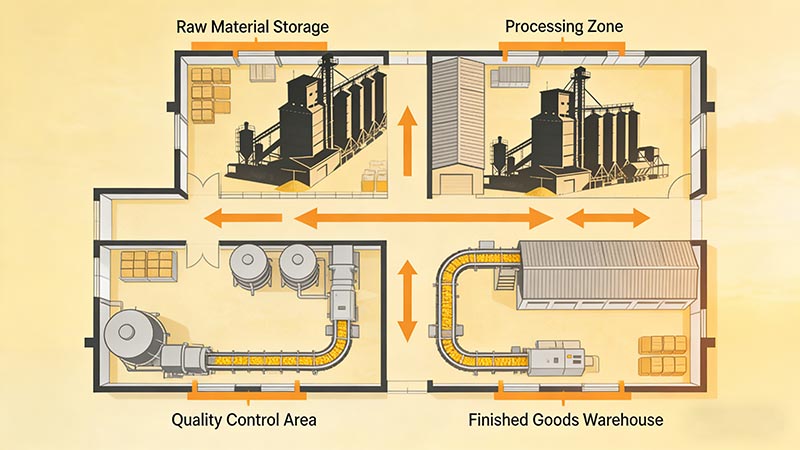

Layout Design To Drive Long-Term Profitability

Maize Flour Mill Factory Layout: Efficiency & Scalability

A standard maize flour plant layout follows a linear or vertical process flow: raw maize receiving → cleaning and conditioning → degermination → milling → sifting → packaging and storage.

-

Material Flow Efficiency:

Straight-through layouts reduce cross-traffic and secondary handling, cutting internal transfer time by 15–20% while stabilizing throughput.

-

Vertical Space Utilization:

Multi-floor designs that rely on gravity for product movement can increase processing capacity per square meter by 10–15%, especially in space-constrained facilities.

-

Operational Safety And Compliance:

Clear separation between raw material zones, milling areas, and finished flour storage reduces contamination risk and supports international food safety standards.

Replicable Layout Principles For Other Flour Mills

-

Maintain independent zones for intake, processing, and packaging to simplify sanitation and production control.

-

Reserve buffer areas of 10–20% additional floor space to accommodate future capacity expansion or new flour types without disrupting existing operations.

Get a maize flour plant layout blueprint designed for efficiency, scalability, and long-term returns—connect with ABC Machinery engineers today.