Ultimate Guide:Starting a Profitable Cassava Flour Mill Business

Cassava flour / Tapioca flour, as an important ingredient in many regions such as Asia, Africa and Latin America, has an increasingly prominent market potential. It is rich in carbohydrates, serving as an important source of energy. Additionally, it contains moderate amounts of protein, vitamins (such as vitamin C, B6, and folate), and minerals (including K, Mg, Fe, and Ca). In recent years, with the popularity of healthy eating trends, cassava flour has become favored by consumers around the world due to its low fat, high fiber and easy digestion characteristics, thus becoming a product with huge commercial potential. Cassava is also relatively easy to grow and has high yields, making the production and sale of cassava flour a lucrative prospect.

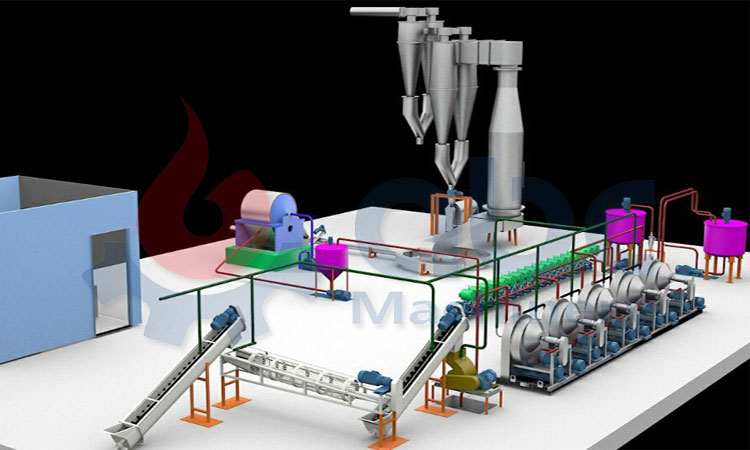

Supply Cassava Flour Milling & Tapioca Equipment

If you are interested in getting into the cassava flour mill project, it is crucial to have a comprehensive business plan. The following will provide you with a detailed analysis of the steps and key points of starting a tapioca flour manufacturing business.

Business Plan: Start a Cassava Flour Processing Plant in 5 Steps

Cassava Flour Starach Production Business Plan

Step 1. Elaborate Planning, Constructing the Cassava Flour Business Blueprint

In this step, we will delve into how to formulate a comprehensive and feasible cassava flour business plan.

-

Firstly, you need to clarify your business model, whether it involves growing and processing cassava yourself or directly purchasing cassava from suppliers for processing.

-

Simultaneously, establish a stable source of cassava and supply channels to ensure the continuity of the production process.

-

Additionally, consider the purchase or leasing of cassava flour processing equipment, as well as market positioning and customer demand.

Step 2. Site Selection Strategy, Establishing an Efficient Cassava Flour Production Base

The choice of production location needs to consider cost, transportation convenience, and market demand comprehensively.

-

For startups, if conditions allow, you can choose to produce at home or in a place with lower rent to reduce costs.

-

For large and medium-sized investors, establishing a cassava flour processing factory requires careful planning and execution. The choice of location is crucial because the factory needs access to water, electricity, and roads. Ideally, the factory should be located near cassava farms to reduce transportation costs and ensure a stable supply of fresh cassava.

Cost-effective Cassava Flour Production Factory in Nigeria

Notes: The cost of acquiring land for a factory may vary greatly depending on the location and local market conditions. Generally, the cost of building a medium-sized cassava flour processing factory ranges from $100,000 to $300,000. This cost includes building materials, machinery, and labor.

Step 3. Market Insight, Positioning the Cassava Flour Business Opportunity

The market demand for cassava flour is extensive, including retail markets, food processing plants, and catering enterprises, among others.

You need to choose the most suitable market positioning based on your product characteristics and competitive advantages. For example, if your cassava flour is of high quality, consider entering the high-end market; if cost control is appropriate, consider gaining a competitive advantage in price-sensitive markets.

Step 4. Equipment Selection, Enhancing Cassava Flour Production Efficiency

Choosing the right cassava flour processing equipment is key to ensuring production efficiency and product quality. When choosing equipment, consider performance, stability, and maintenance costs. At the same time, you can use internet resources to compare shopping and find equipment suppliers with high cost performance.

It is worth mentioning that our company, ABC Machinery, as a professional manufacturer of cassava flour processing equipment, has many years of production experience and a professional technical team. We can provide you with high-quality equipment and comprehensive pre-sales, in-sales, and after-sales services to ensure the smooth progress of your production process.

Step 5. Marketing Strategy, Promoting the Cassava Flour Brand

Effective marketing strategies are crucial for enhancing product visibility and sales. You can promote through online platforms, industry exhibitions, product launches, etc., to establish contact with potential customers. Additionally, consider collaborating with food manufacturers, catering companies, etc., to expand sales channels.

When planning a cassava flour manufacturing business, controlling costs and improving efficiency are equally important. By selecting the right equipment, optimizing production processes, and fine-tuning market positioning, you can stand out in a competitive market and achieve substantial profits. (Related Post: Setup Mazie Flour Production Plant Cost)

In a word, starting a cassava flour milling business requires comprehensive consideration of many aspects, from developing a business plan to selecting production equipment, and then to formulating marketing strategies, all of which require careful planning and execution. If you encounter any problems or need professional advice during this process, please feel free to contact us at ABC Machinery. We will wholeheartedly provide you with support and services to help you successfully start your cassava flour production business journey!

Investment Analysis: Profit Potential and Prospects of Cassava Flour Production Factory

With the global demand for cassava flour continuously growing, starting a cassava processing business has enormous profit potential. According to recent statistics, the global demand for cassava flour has increased by over 15% in the past five years, indicating a steady rise in market demand for cassava flour. Experts predict that by 2025, the global cassava flour market will be worth approximately $1.5 billion.

| Cassava Flour Consumption Growth Rate | 3.7% annually |

|---|---|

| Key Cassava Flour Exporters | Nigeria, Thailand, Indonesia |

| Market Segmentation (Food and Beverages) | Over 60% market share |

Moreover, advancements in technology have led to the development of more efficient and cost-effective cassava flour processing equipment. For instance, modern cassava flour processing machines can increase production capacity by up to 30% while reducing energy consumption by 20% (Source: ABC Machinery Company). Such technological advancements not only enhance production efficiency but also contribute to cost savings in the long run.

In conclusion, developing a comprehensive cassava flour business plan is crucial for successful entrepreneurship. This plan will assist you in understanding and controlling various costs, providing solid support for future cassava flour processing business development. If you have any queries or requirements regarding cassava flour production project construction, please feel free to contact us! ABC Machinery Company is dedicated to providing professional consultation and services.