Millet Flour Mill Business: Startup Guide and Market Planning

Have you ever noticed the surging demand for gluten-free, nutrient-dense millet flour—driven by health trends and regional dietary preferences, and wondered how to turn this growing market into a profitable business?

Start Millet Flour Mill Business: Key Steps & Equipment

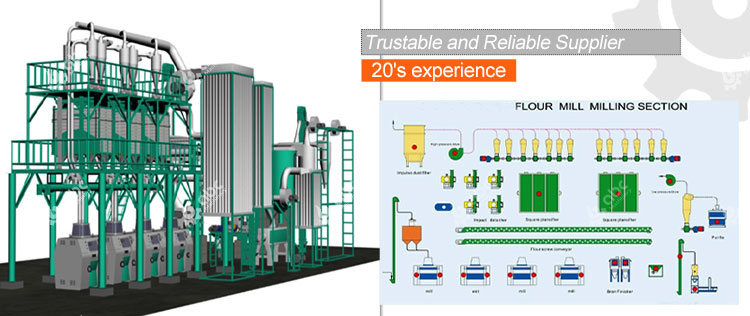

As part of the Start Flour Mill Business Plan for Different Grains, this guide breaks down everything you need to launch and scale a millet flour mill, from equipment selection to market strategies, ABC Machinery has over 20 years of experience in flour equipment manufacturing, flour milling machinery production, grain flour mill construction, and the supply of supporting equipment such as millet processing equipment, maize milling machines, corn grinding machines, and grain processing plants. If you have any related needs or questions, please feel free to contact us at any time.

What Key Preparations Lay the Groundwork for a Successful Millet Flour Mill?

Before investing in millet mill equipment or securing a flour mill plant, thorough preparation ensures you avoid common pitfalls.

1. Market Research: Understand Demand and Competition

Start by answering: Who will buy your millet flour, and what gaps exist in the market? Conduct research to:

-

Identify regional preferences (e.g., demand for organic millet flour in urban areas vs. bulk millet flour for rural food stalls).

-

Analyze competitors: Do they offer fortified millet flour? What pricing strategies do they use?

-

Study global trends: Gluten-free diets are driving millet flour demand in Europe and North America, while regional markets (e.g., Nigeria, Pakistan) use millet in traditional dishes. (Reference regional flour mill business guides in Nigeria )

2. Regulatory Compliance: Secure Licenses and Permits

No flour mill setup is complete without legal clearance. Requirements vary by location but typically include:

- Food safety certifications (e.g., FSSAI in India, FDA in the U.S.) to ensure your millet flour production meets health standards.

-

Environmental permits (critical for grain processing equipment that may generate dust or waste).

-

Business registration (sole proprietorship, LLC, or partnership) to formalize operations.

3. Budget Planning: Estimate Costs for Startup and Operations

Create a detailed budget covering:

-

Millet mill investment: Includes land (for a grain processing plant), construction, and utilities.

-

Equipment costs: From small mill machines ($5,000–$20,000) to large flour production lines ($50,000–$200,000).

-

Operational expenses: Raw millet (source from local farmers for cost savings), labor, and maintenance.

How to Choose and Optimize Millet Processing Equipment for Efficiency?

Large Millet Flour Processing Production Project

Your millet processing machinery is the backbone of your business, choosing the right tools ensures consistent quality and high output.

Core Equipment for Millet Flour Production Lines

A standard millet flour mill requires 5 key machines (adapted from wheat and corn mill setup best practices):

-

Cleaning machine: Removes impurities (stones, dirt) from raw millet to protect downstream equipment.

-

Dehulling machine: Separates millet hulls (critical for white millet flour; optional for whole-grain varieties).

-

Grinding machine: Converts dehulled millet into flour (choose between stone mills for artisanal quality or stainless steel mills for high volume).

-

Sieving machine: Filters flour to ensure uniform particle size (adjustable for fine or coarse millet flour).

-

Packaging machine: Automates weighing and sealing (essential for branding and shelf life).

Millet Processing Equipment Comparison Table

Use this table to select equipment based on your business scale:

| Equipment Type | Key Function | Suitable Business Scale | Estimated Cost Range | Complementary Tools |

|---|---|---|---|---|

| Small Millet Mill | Basic cleaning + grinding | Home-based/ small-scale | $3,000–$8,000 | Manual packaging tools |

| Medium Flour Line | Automated cleaning + dehulling | Local commercial mills | $20,000–$50,000 | Semi-automatic sieving |

| Large Processing Plant | Full production line (cleaning to packaging) | Industrial/ export-focused | $80,000–$250,000 | Quality control systems |

3 Tips to Optimize Equipment Performance

-

Regular maintenance: Schedule monthly checks for grain mill machines (e.g., lubricate grinding parts, clean sieves) to avoid breakdowns.

-

Train staff: Ensure operators understand how to adjust flour manufacturing equipment (e.g., grinding speed) for different millet varieties.

-

Energy efficiency: Choose LED lighting for your flour mill plant and invest in energy-saving motors (reduces operational costs by 15–20%).

What Market Strategies Drive Sales for Millet Flour Mill Businesses?

Millet Flour Mill Plant Design & Supply

Even the best millet flour project fails without a solid market plan. This section covers target audience segmentation, promotion, and distribution.

1. Define Your Target Customers

Segment your audience to tailor products and messaging:

-

Household consumers: Market small-pack (1–5kg) organic or fortified millet flour (highlight health benefits: high fiber, iron).

-

Food manufacturers: Supply bulk millet flour for snacks, bread, or baby food (emphasize consistency and competitive pricing).

-

Export markets: Target gluten-free brands in Europe or North America (obtain organic certifications to command premium prices).

2. Multi-Channel Promotion Strategies

-

Online marketing:

Launch a website showcasing your millet flour production process and certifications.

Use social media (Instagram, Facebook) to share recipes (e.g., millet rotis, pancakes) and customer testimonials.

-

Offline tactics:

Participate in food expos to demo your flour (partner with local bakers for live tastings).

Distribute brochures to supermarkets and grocery stores (offer trial packs to encourage shelf placement).

-

Collaborations:

Partner with nutritionists to promote millet flour as a healthy alternative to wheat (boosts credibility).

3. Build Sustainable Distribution Networks

-

Local supply chains: Work with local farmers to source millet (reduces transportation costs and supports community).

-

Wholesale partnerships: Partner with distributors to reach rural areas.

-

Direct sales: Offer home delivery for urban customers (use apps or WhatsApp to take orders—low-cost and convenient).

Ready to turn your plan into action? Use these resource types to deepen your knowledge:

-

For a customizable business plan template: Explore adaptable templates originally designed for maize milling business plans (easily adjusted for millet).

-

Small-scale startup advice: Seek guides focused on flour mills for small businesses, including equipment selection and budget planning tips.

-

Regional insights: Consult location-specific business plans (e.g., Pakistan, Ethiopia) to align your millet mill with local market needs and regulations.

-

Equipment comparisons: Refer to cost analysis guides for wheat flour mill equipment to evaluate grain processing equipment pricing and performance.

As the global demand for healthy, sustainable grains continues to rise, now is the perfect time to launch your millet flour mill business. With the right preparation, equipment, and market strategy, you can build a profitable venture that meets consumer needs. So why wait? Are you ready to take the first step toward becoming a leader in the millet flour industry?