Oat Mill Project: Investment Strategy and Business Plan for Profitable Flour Production

In recent years, the global demand for healthy, whole-grain products has surged, with oat-based foods emerging as a top choice for consumers seeking fiber-rich, gluten-free alternatives. This trend has turned the oat mill business into a high-potential venture, distinct yet complementary to traditional grain mill operations like corn mill and wheat mill.

How to Start A Oat Flour Milling Plant Business?

Unlike conventional flour mill plants focused on wheat or corn, an oat mill leverages specialized oat processing equipment and oat milling machine to produce oat flour— a product now in high demand across bakeries, health food brands, and households. This article breaks down the key steps to build a profitable oat mill, integrating essential elements of flour mill business best practices and grain processing expertise.

Market Analysis & Demand Assessment for Oat Mill Ventures

Before committing to oat mill business investment, a thorough market analysis is critical to validate demand and identify competitive gaps. Globally, the oat flour market is projected to grow at a CAGR of 6.2% through 2030, driven by rising health consciousness and the popularity of plant-based diets. And oat consumption is expanding beyond urban areas, creating opportunities for localized oat mill setup.

Key factors to evaluate include:

-

Consumer Buying Trends: Modern consumers prioritize products with “clean labels,” making oat flour production a viable niche compared to refined wheat flour (processed in standard wheat mill facilities).

-

Competitive Landscape: Assess existing grain processing plants and flour mill businesses in your target area. Many traditional flour mill plants focus on wheat or corn (using corn mill machinery or wheat mill equipment) but lack specialized oat milling capabilities. This gap allows new entrants to differentiate by offering oat flour alongside complementary products (e.g., mixed grains from a multi-functional grain milling machine).

-

Supply Chain Access: Oat mill operations depend on consistent raw material supply. Proximity to oat farms reduces transportation costs, while partnerships with local farmers ensure quality.

By aligning your oat mill project with these market insights, you can tailor your offerings to meet unmet demand—whether supplying small bakeries with fresh oat flour or partnering with large food manufacturers for bulk orders.

How to Invest Your Own Oat Flour Milling Plant Business?

A sound oat mill investment strategy balances cost control, equipment quality, and long-term profitability. Unlike a basic mill machine or small flour mill setup, an oat mill requires specialized tools to handle oat’s unique texture (softer than wheat, more fibrous than corn).

Setting a Oat Flour Mill Cost (Budget Allocation)

-

1. Equipment Costs (40-50% of Total Investment):

The largest expense is oat processing equipment, including oat milling machine, oat flour mill units, and auxiliary tools like grain cleaning machines (a staple in all grain mill operations).

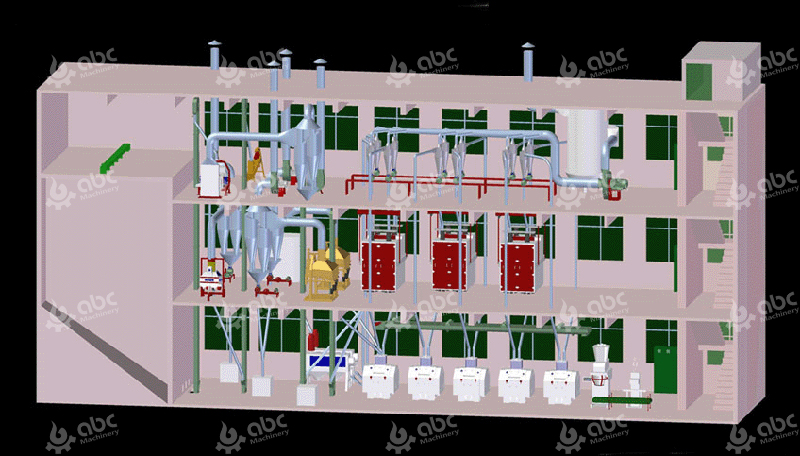

Large Flour Milling Project

For a mid-scale oat mill plant, expect to invest in a complete oat flour production line—integrating hullers, rollers, sifters, and packaging machines, rather than standalone mill equipment. Compare suppliers of flour milling machinery to ensure durability; reputable brands (like ABC Machinery) offer equipment compatible with future expansion (e.g., adding a wheat mill module later).

-

2. Infrastructure (20-25%):

A standard oat mill setup requires a 1,000-1,500 sq. ft. facility (smaller than a full-scale grain processing plant) with proper ventilation and storage for raw oats. Costs include leasehold improvements, electrical wiring for heavy-duty grain processing machinery, and safety features (e.g., dust control systems, mandatory in all flour mill plants).

-

3. Operating Capital (20-25%):

Reserve funds for raw material purchases (initial 3-6 months of oat stock), labor (3-5 staff for production and quality control), and marketing (promoting your oat flour to local flour mill businesses and retailers).

-

4. Contingency (5-10%):

Set aside funds for unexpected costs, such as equipment repairs or delays in obtaining grain processing plant permits.

Operational Plan for Sustainable Oat Mill Business

Once investments are finalized, a detailed operational plan ensures your oat mill runs efficiently, meets quality standards, and scales over time.

1. Production Process Optimization

A typical oat flour production line follows these steps, using specialized oat processing equipment:

-

Raw Material Preparation: Clean oats to remove impurities (stones, chaff) using grain cleaning machines (common in all grain mill operations).

-

Hulling & Dehulling: Use an oat milling machine to remove the hard outer hull—critical for producing smooth oat flour.

-

Milling & Grinding: Pass dehulled oats through a roller mill (part of standard flour milling machinery) to create coarse flakes, then refine them into flour using a hammer mill or pin mill (specialized oat processing equipment).

-

Sifting & Quality Control: Use sifters (integrated into the oat flour production line) to ensure consistent particle size. Test samples for moisture content and purity—standards similar to those in wheat mill or corn mill operations.

-

Packaging & Storage: Package oat flour in airtight containers (to preserve freshness) and store in a cool, dry area of your flour mill plant.

2. Supply Chain & Distribution

-

Raw Material Sourcing: Partner with 2-3 local oat farmers to ensure a steady supply. Negotiate long-term contracts to lock in prices, as done by successful grain processing plants.

-

Distribution Channels: Target three key segments:

(1) local bakeries and cafes (small-batch orders)

(2) health food stores (premium organic oat flour)

(3) large food manufacturers (bulk orders via your grain processing machine’s high-capacity output).

3. Quality Control & Branding

-

Consistency: Use advanced grain milling equipment with automated controls to maintain uniform oat flour quality—this differentiates your business from small-scale mill machine operators.

-

Branding: Highlight your oat mill’s strengths, such as “100% Organic” or “Locally Sourced,” to appeal to health-conscious consumers. This is analogous to how flour mill businesses market specialty wheat flour.

For those ready to embark on this journey, take actionable steps today:

-

Connect with Trusted Suppliers: Reach out to manufacturers of oat milling machine and grain processing equipment to request quotes and customized oat mill setup plans.

-

Validate Local Demand: Conduct on-site surveys in your target region to understand buyer needs—whether for organic oat flour or bulk industrial supply.

-

Finalize Your Business Plan: Integrate insights from this article with local regulations (e.g., grain processing plant permits) to create a tailored flour mill project proposal.

Don’t miss the chance to tap into the $8 billion global oat market—start your oat mill investment today and join the ranks of profitable grain processing entrepreneurs! Welecome to contact us for complete professional information to fulfill your flour milling business plan so as to make it success.